Liquid Nitrogen Plant

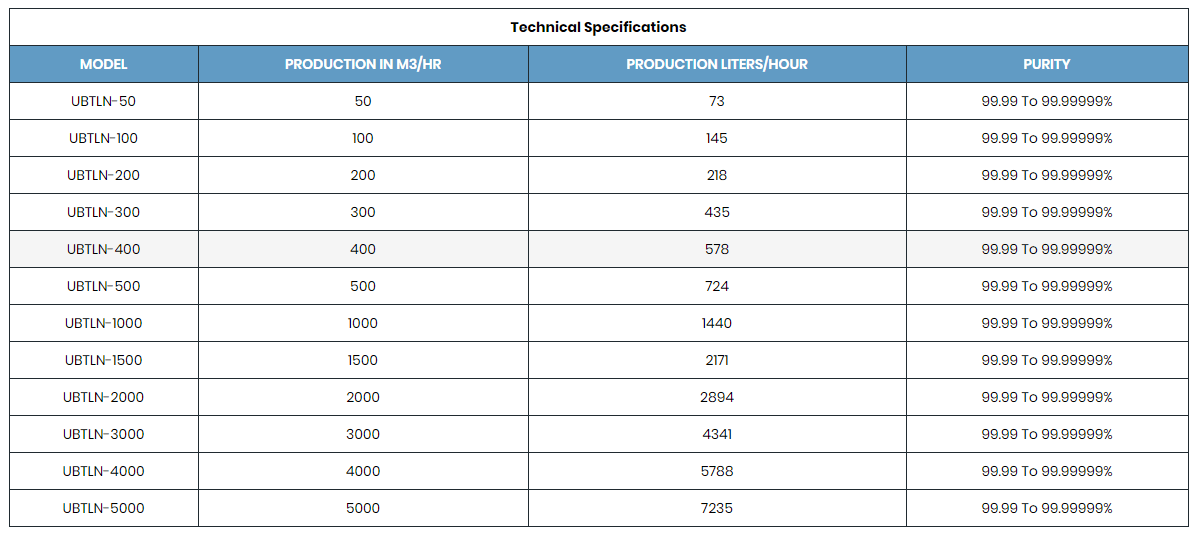

Product Capacity : UBTLN-50 Litre/hr To 10,000 Litre/hr

Description

Liquid nitrogen plants are made with the latest technology and ASME standard materials to generate LN2 in capacities ranging from 50litres/hr to 5000litres/hr for industrial and medical uses.

We manufacture and supply LN2 Plants for wide range of industries including steel, chemical, Food, Petroleum, Pharmaceutical, etc. Our LN2 production machinery is reliable, efficient and durable. Moreover, our LN2 plants use cryogenic air separation cycle which is the most advanced technology available for air separation and nitrogen purification. Engineers and technicians at our factory are continuously updating our product catalogue to meet the requirement of our customers more efficiently with low power consumption and operating costs. Needless to say, our plants are fully automated with PLC system from Siemens and can work even unattended. In case, there is a mal-function, the system is equipped with remote diagnostic monitoring and troubleshooting tools for identifying the problem and setting it right. And, life span of our cryogenic air products is over 35 years.

What is Cryogenic Distillation Process for LIN?

Cryogenic distillation starts with the intake of atmospheric air into the inlet of air separation unit (ASU). Afterwards, the air is compressed and is run though purification unit for removal of impurities such as hydrocarbons, carbon dioxide and water vapors. However, it is essential that impurities are removed before the air moves into the cryogenic distillation column. There is probability of impurities getting frozen at cryogenic temperatures and get deposited on surfaces within the column. We use molecular sieves for purification as well as in high nitrogen recovery. Then, the treated air is fed into a series of heat exchangers for cooling it to cryogenic temperatures. Now the liquefied air enters high pressure distillation column where nitrogen gets separated from oxygen, argon and other rare gases. Now the product gas, nitrogen, enters low pressure distillation column for achieving the desired purity. We are acclaimed for making the best quality air separation columns with 100% cryogenic grade stainless steel for durable and reliable performance. No doubt, the column is called the heart of the LN2 Plant contributing over 60% to the performance of the plant so needs manufacturing only with high quality materials and components.